For a decade now, German authorities have been supporting the very ambitions ‘Energiewende’ – “energy turnaround.” The highly innovative German industry is a promising sector for optimizing energy consumption. But how do you take action without jeopardizing the competitiveness of German industry and the German production system? There are several possible scenarios, including energy conservation and digitalization.

Energy management in Germany

Energiewende: bold ambitions…

The energy transition policy, initiated in Germany almost a decade ago, set a highly ambitious goal for the end of 2022: to generate electricity using renewable energy sources without resorting to nuclear power.

Energiewende therefore aims to lead Germany towards a low-carbon energy system by 2050. Coal would be phased out by 2038, even though it is still, to this day, the main source of energy for electricity generation.

… and updated targets

Germany is currently struggling to meet its targets for greenhouse gas (GHG) emissions reduction. The increased use of renewable energy sources in its electricity generation has enabled it to reduce its emissions, but this progress has been partly limited by the phase-out of nuclear power and an increasing electricity export surplus.

In this context, the German government has had to lower its targets. Their new planned target is to reach a share of 65% renewable electricity by 2030. Both policy and regulatory reforms can help Germany achieve a cost-efficient, equitable and sustainable pathway to meeting its highly ambitious energy transition goals. But Germany must also be able to count on its industry.

The role of industry in these energy targets

Competitive and innovative, German industry has a key role to play in this energy transition. Indeed, it is one of the sectors that is most dependent on fossil fuels.

An innovative and competitive sector...

Ranked the fourth largest globally by production, the German automotive industry is regarded as one of the most competitive and innovative in the world. Germany is one of the leading exporters of machinery, chemicals and household equipment.

… with high energy consumption

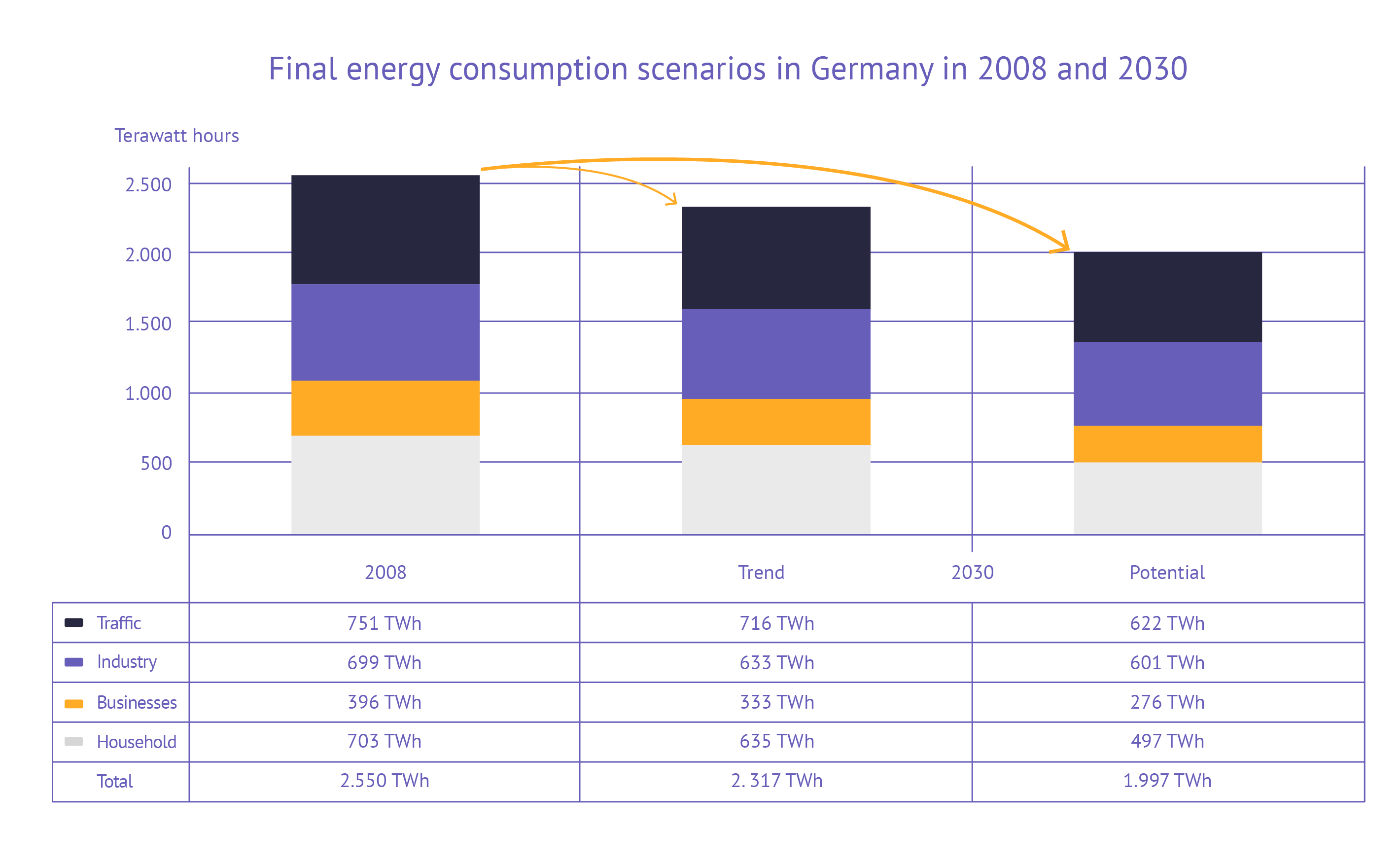

The industry sector is the single largest energy consumer accounting for over a third of the country's total final consumption in 2017. This includes fuels used for non-energy purposes, which represent 28% of total industrial consumption, mainly oil and gas in the chemical and petrochemical industry.

The following diagram illustrates the potential for an overall reduction in consumption by 2030, in particular in industry:

Energy management is a strategic matter for German manufacturers. However, the Federal Ministry is keen to ensure that this quest for energy performance does not jeopardize the competitiveness of German industry. So, how do you go about it?

Energy and industry in Germany: what are the possible solutions?

The least polluting energy will always be the energy we don't use! Energy conservation, which is based on managing and changing the ways we use energy, appears to be an ideal solution.

However, a key parameter also needs to be taken into account: the economic reality. This is a key issue for manufacturers in order to reduce consumption while maintaining the quality and volume of production. For consumption that cannot be avoided, this means moving towards greater energy efficiency. German industry is therefore considering new solutions for monitoring consumption with a view to optimizing it. To do so, it is necessary to digitalize businesses.

#1 An essential digital transformation

In its 2020 report on energy management in Germany, the International Energy Agency (IEA) set out several recommendations in line with digital transformation. Firstly, it suggests promoting flexibility of energy supply and demand by further developing market regulation and digitalization.

This involves better regulating supply and demand:

- by exposing electricity producers and consumers to real-time market prices

- further integrating both wholesale and balancing markets with neighbouring electricity systems

The IEA also suggests redirecting the funding under the 7th Energy Research Programme of the Federal Government on energy transition challenges. To this end, intersystem research areas, such as digitalization and resource management, are priorities.

#2 Digital solutions to optimize consumption

To reduce consumption, we must first have a clear understanding of what consumption is and understand the impact of different influential factors. Providing this insight, digitalization is the first step towards a global Energy Management approach. From there, it needs to be exploited.

Certain digital solutions also offer consumption monitoring with a view to optimizing it. By combining human expertise with cutting-edge technology, digital solutions help provide a good understanding of the industrial context and enable you to qualify the data. Their system can then learn the operation of the machines and their production context in order to optimize energy consumption in real-time.

For the same level of production of the same quality, it is therefore possible to reduce energy consumption and limit its impact on the environment. These digital tools therefore have a major role to play in the range of solutions that meet the energy challenges addressed by the German government with Energiewende.

[Infographic] HOW DIGITAL IS MAKING ITS MARK ON ENERGY MANAGEMENT >

The challenges of Energiewende offer German industry numerous opportunities in terms of energy management. Businesses can now rely on innovative solutions, whatever their digitalization maturity. Do you want to find out more about METRON energy intelligence solutions? Contact us!