METRON offers an industry 4.0 approach to energy management, providing a platform that combines AI-based technology and human expertise. The solution collects, aggregates and analyzes data in real-time to optimize energy consumption.

Successful application for the cold chain

A customer producing 150-200t/day of frozen meat for the catering industry, with 45GWh/year of electricity consumption - including 21GWh/year on the optimized perimeter (chiller) - wanted to digitalize his plant and improve energy efficiency within his factory.

METRON’s actions:

All historical and real-time data available in the plant (PC/PLC, sensors, SCADA, Servers, management system, etc.) were collected and aggregated in the METRONLab, then sent to the cloud to be integrated with external influential data (weather data, energy markets and bills, etc.). This data coupled with the customer knowledge of the industrial process, and METRON’s energy expertise and technology, generated real-time recommendations through dedicated dashboards.

Results:

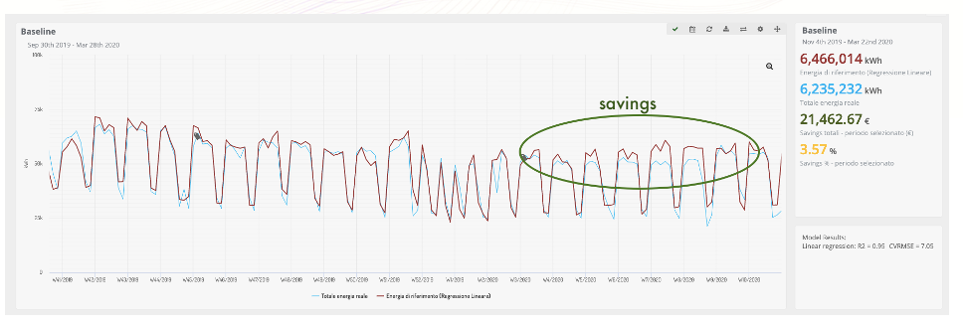

The client benefited from custom dashboards automatically suggested by the AI, plant overview production control with KPIs per production batch and efficient baselines for real-time alerts in case of drift in consumption.

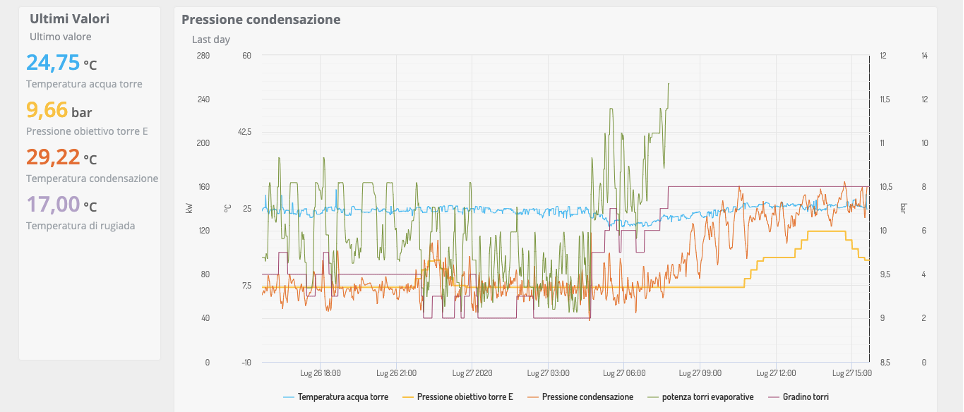

Before the intervention the condensation pressure set point varied seasonally (2-3 times a year); today suggestions are issued every 15 minutes depending on the external weather conditions. METRON’s platform integrates data from a weather station near the site and recommends the optimal condensation pressure level by transferring it to the customer's PLC, according to the external dew point and the load of the plant. This optimization allows to satisfy production capacity, product quality and plant safety, while generating savings: €45,000 obtained from January to July 2020).

Want to know more?